Robotics is an emerging field in the world which is bringing drastic changes in

human life. Robots are designed in human interactive way and they are becoming

part of lives. Human power is being saved by replacing it by robots in various

fields. Cleaning public places is one such field where more human power is

required. Autonomous trash collecting robots have been considered as benchmark

for mobile robot design problem. These include several common tasks such

as navigation, path planning, object detection and discrimination, obstacle

avoidance, task sequencing and often multi-agent coordination.

The major public problem faced by many developing countries, especially

in India, is lack of uncollected trash littering the streets, roads, sidewalks,

shopping malls, railway and bus stations and many other public places.

An autonomous robot is a robot which performs behaviors or tasks individually

with highest degree of autonomy. These are mainly desirable in fields such as

household maintenance cleaning, waste water treatment spaceflight, delivering

goods and other services. Some of the modern factory robots are allowed to be

autonomous within the strict boundaries of their environment. Every degree of

freedom may not exist in their surrounding environment, but the factory robot’s

workplace is challenging, can contain unpredicted variables and can be often

chaotic. An autonomous robot can obtain information about its surrounding

environment, work for more time without human intervention, move either all or

part of itself throughout its operating environment without human

assistance, avoid situations that are harmful to humans, public property, or itself

unless those are specified in design specifications. They can also adapt to

changing surroundings. Like other machines, these robots need regular

monitoring and maintenance for proper performance.

TRASHBOT has an IOT interface with autonomous and manual mode of control. The trash is picked up using robotic arm.The picked up trash is segregated (metallic and nonmetallic) and dumped into bin attached to the robot which has separate partitions for metallic and nonmetallic trashes.If the trash bin gets filled it is notified to the person operating the robot as message in the IOT interface. The entire operation of waste collection can be viewed by the operator through internet using a mobile camera attached to the robot.

view the working:

CONCEPT

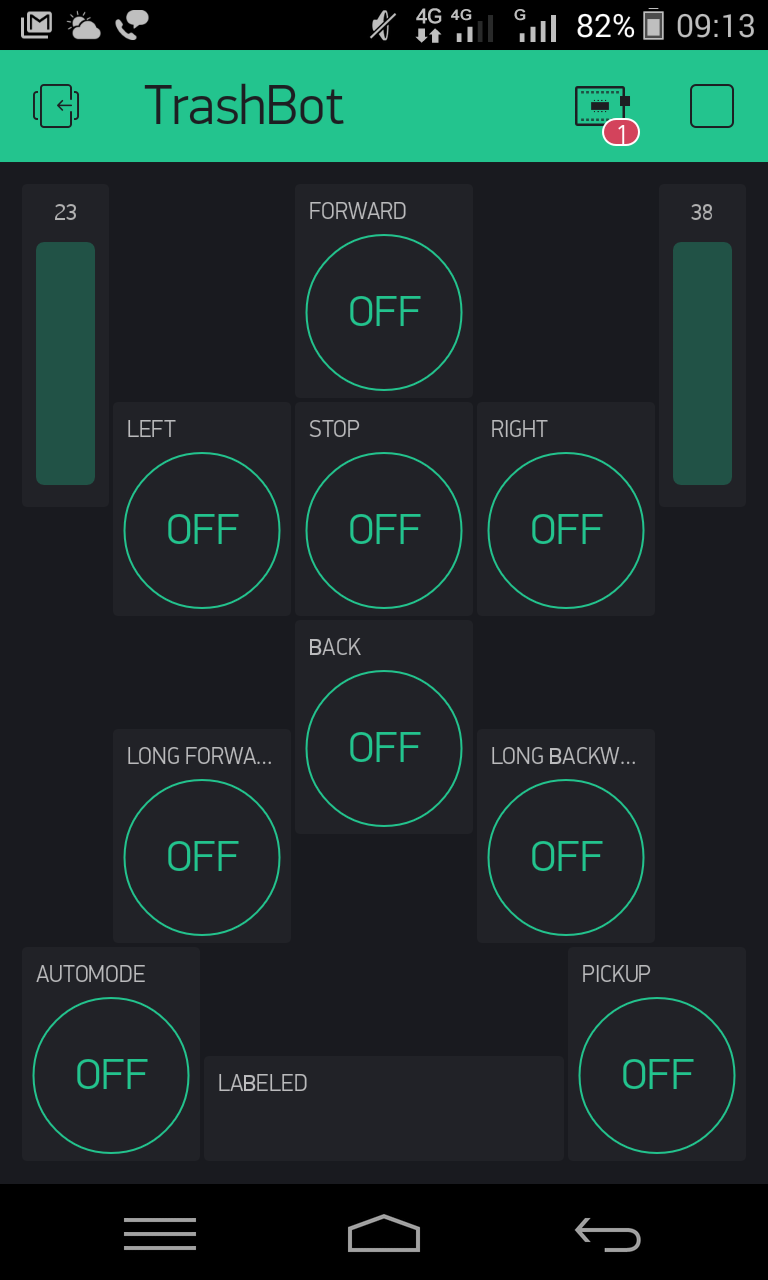

In manual mode the robot locomotion and trash pickup is operated using an android phone

through blynk app.The robot can be controlled from anywhere in the world by the use of internet(IOT). For the vision of robot an android phone is placed in the robot and live streaming is made possible using ip webcam android app.

The trash is picked up using robotic arm made using 3 servos.

Using this ultrasonic sensor configuration the robot will be able to distinguish between big objects(walls) and objects that it may be able to pick.Big objects are considered as obstacles by the robot and are avoided. Other objects are considered as trash and are picked up by the robotic arm.

This battey is capable of delivering 20A so that 5A can be utilized by each motor attached to the wheel.

CONCEPT

The robot is operated using an android

mobile phone and a laptop.

2 operating modes

1.Manual mode

2.Autonomous mode

In manual mode the robot locomotion and trash pickup is operated using an android phone

through blynk app.The robot can be controlled from anywhere in the world by the use of internet(IOT). For the vision of robot an android phone is placed in the robot and live streaming is made possible using ip webcam android app.

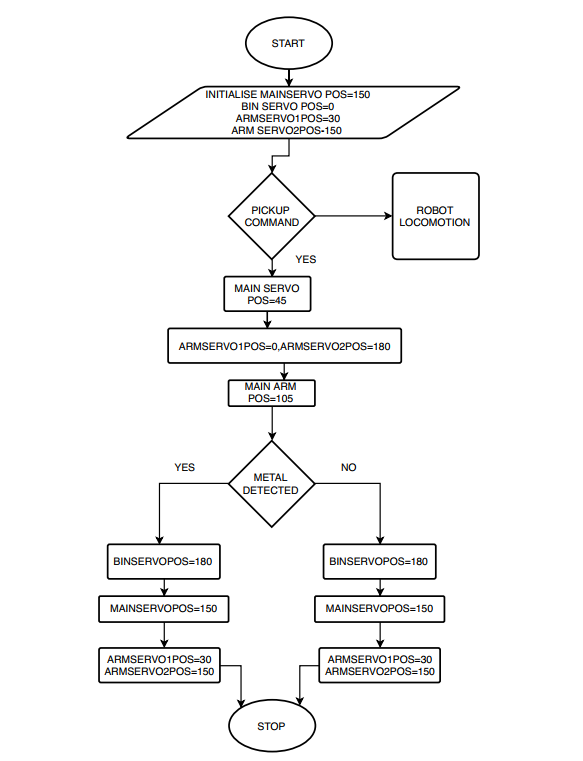

The trash is picked up using robotic arm made using 3 servos.

The collected trash is transferred to a trash bin attached to the robot platform. The trash bin has separate partitions for metallic and nonmetallic trashes. Another Servo motor attached to the trash bin will rotate the bin so that the collected waste will fall into the corresponding partition of the bin.

In autonomous mode the robot locomotion and waste pickup is done without human intervention. The robot is placed at the centre of the workspace. Then it follows a coverage path planning algorithm/random path planning alogithm . The trash detection is made possible using 4 ultrasonic sensors placed in 2 rows (2 in one row).The sensing range is limited to about 30cm to avoid crosstalk.

Using this ultrasonic sensor configuration the robot will be able to distinguish between big objects(walls) and objects that it may be able to pick.Big objects are considered as obstacles by the robot and are avoided. Other objects are considered as trash and are picked up by the robotic arm.

Metal detectors placed in the arm check

the trash picked to be metallic or nonmetallic

and are dumped its corresponding partition in the trashbin.

Ultrasonic sensor placed in the trashbin monitor

the level of the waste in the bin.If the bin

is full it is notified to the operator.

BLOCK DIAGRAM

COMPONENTS USED

1.Arduino Mega 2560 : microcontroller board based on the ATmega2560

Buy this from here: http://zipansion.com/3u6Xb

2.Servo motors:

Buy this from here: http://zipansion.com/3u6Xb

2.Servo motors:

ULTRA TORQUE DUAL SHAFT METAL GEAR 35KGCM CORELESS SERVO

This is the main servo which pulls the robotic arm up and down.

Buy this from here: http://zipansion.com/3u6as

HIGH TORQUE DIGITAL SERVO MOTOR 180° 20KGCM

This servo is used to rotate the trashbin based on whether the picked up trash is a metal or nonmetal.

Buy this from here: http://zipansion.com/3u6eK

2 of this servos are used to grab the trash by rotation of arm as shown in the video.

Buy this from here:http://zipansion.com/3u6ha

3. LI-ION 11.1V 10000MAH (2C) WITH INBUILT CHARGER-PROTECTION

Buy this from here: http://zipansion.com/3u6jq This battey is capable of delivering 20A so that 5A can be utilized by each motor attached to the wheel.

4.ESP8266 WIFI MODULE

Buy this from here: http://zipansion.com/3u6oZ

used to provide wifi and internet facilities to the microcontroller.

5.LM1117 3.3V OUTPUT BREAKOUT BOARD BREADBOARD POWER SUPPLY

ESP8266 is strictly specific in its voltage rating of 3.3V. LM1117 is used to serve this purpose.Connecting ESP8266 directly to the arduino's 3.3V supply might not serve the amperage needs.

Buy this from here: http://zipansion.com/3u6r7

6.STEP DOWN DC-DC ADJUSTABLE VOLTAGE REGULATOR

used to stepdown the battery's voltage to the required voltage of servo motors.

STEP DOWN DC-DC ADJUSTABLE VOLTAGE REGULATOR 5A (XL4015E1 BASED)

Buy this from here:http://zipansion.com/3u6t3

STEP DOWN DC-DC ADJUSTABLE VOLTAGE REGULATOR 3A OUTPUT

Buy this from here:http://zipansion.com/3u6w0

7.DUAL DC MOTOR DRIVER

the function of motor drivers is to take a low-current control signal and then turn it into a higher-current signal that can drive a motor.It can also change the rotational direction of a motor.

Buy this from here: http://zipansion.com/3u6yK

8.USB TO TTL MODULE

used to flash esp8266 wifi module with the latest blynk compatible firmware.

Buy this from here: http://zipansion.com/3u72L

Refer to this video for knowing how to flash ESP8266 with latest blynk compatible firmware :http://zipansion.com/3u75O

Refer to this video for knowing how to flash ESP8266 with latest blynk compatible firmware :http://zipansion.com/3u75O

9.METAL PROXIMITY SENSOR

used to check whether the trash picked up is a metal or nonmetal.

SOFTWARES USED

1.BLYNK ANDRODID APP: for IOT connectivity.

2.ARDUINO IDE: for programming the audio 3.IP WEBCAM ANDROID APP: for live streaming. 4.ESP8266 FLASH DOWNLOADER:for flashing ESP8266 with blynk compatible firmware.

IOT INTERFACE

FLOW CHART

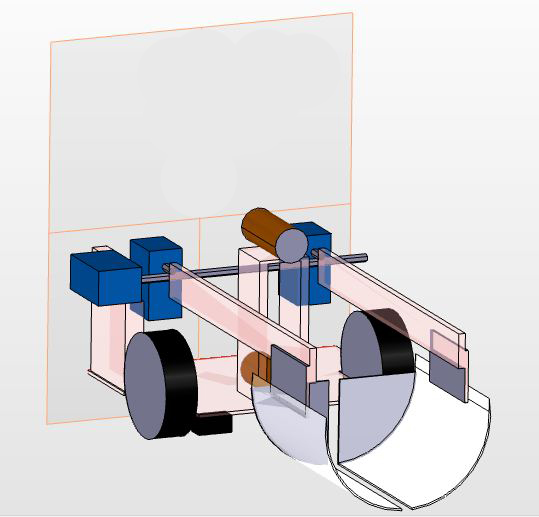

MECHANICAL MODEL

ROBOTIC ARM

CIRCUIT DIAGRAMS

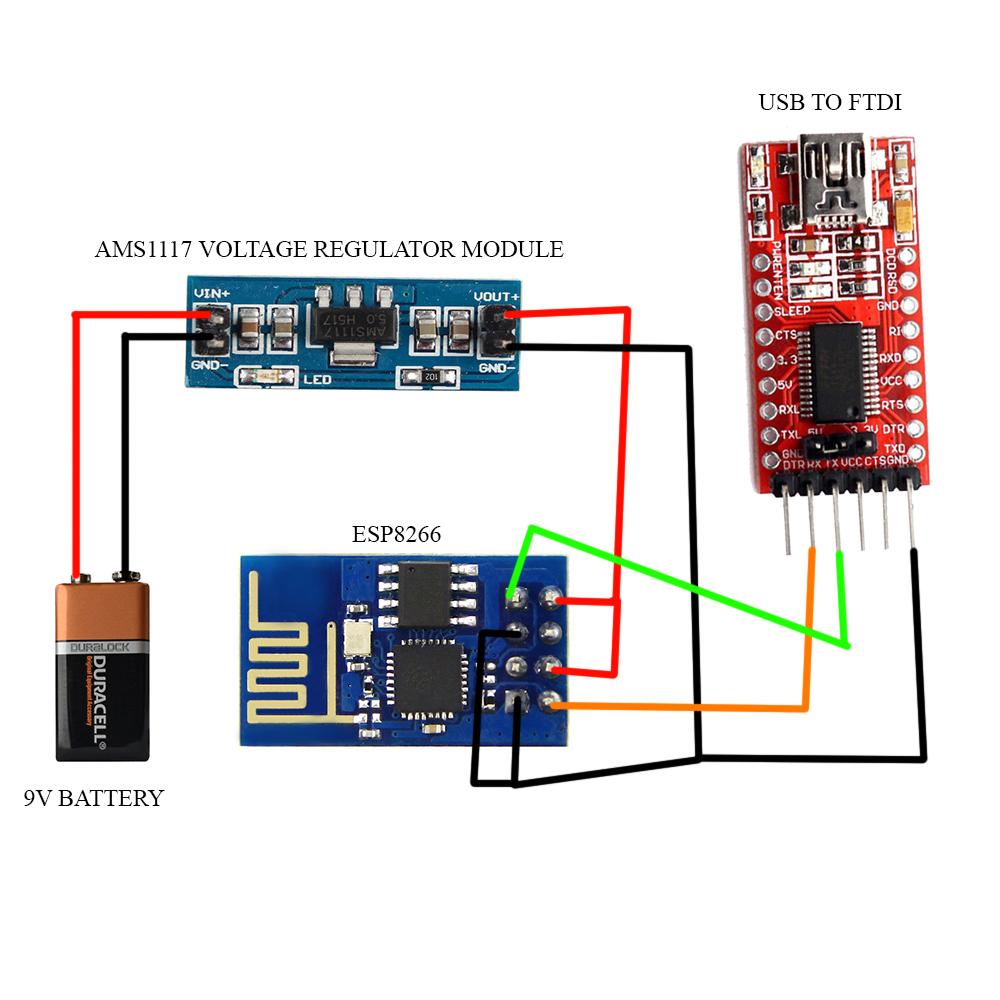

1.ESP8266 flashing circuit

Buy this from here:http://zipansion.com/3u78u

10.ULTRASONIC SENSOR

used for detecting trashes and obstacles.

Buy this from here: http://zipansion.com/3u7Cl

10.ULTRASONIC SENSOR

used for detecting trashes and obstacles.

Buy this from here: http://zipansion.com/3u7Cl

SOFTWARES USED

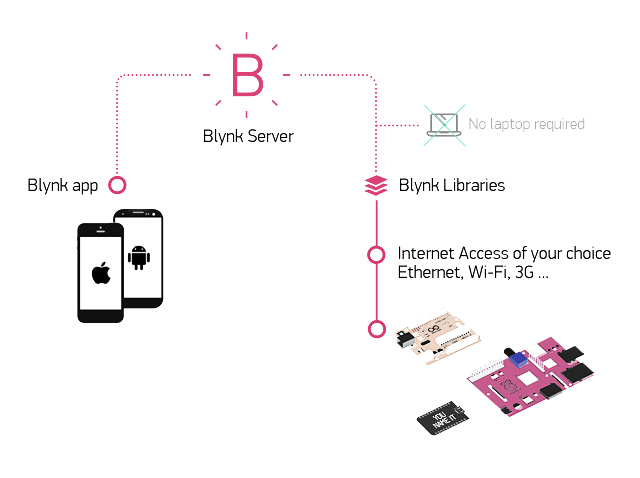

1.BLYNK ANDRODID APP: for IOT connectivity.

- Blynk is a Platform with iOS and Android apps to control Arduino, Raspberry Pi and the likes over the Internet.

- Blynk will get you online and ready for the Internet Of Your Things.

- There are three major components in the blynk platform:

Blynk App - allows to you create amazing interfaces for your projects using various widgets we provide.

Blynk Server - responsible for all the communications between the smartphone and hardware. You can use our Blynk Cloud or run your private Blynk server locally. It’s open-source, could easily handle thousands of devices and can even be launched on a Raspberry Pi.

Blynk Libraries - for all the popular hardware platforms - enable communication with the server and process all the incoming and outcoming commands.

2.ARDUINO IDE: for programming the audio 3.IP WEBCAM ANDROID APP: for live streaming. 4.ESP8266 FLASH DOWNLOADER:for flashing ESP8266 with blynk compatible firmware.

IOT INTERFACE

FLOW CHART

MECHANICAL MODEL

ROBOTIC ARM

The movement of the arm is made possible using 3 servos(35kg-cm,2x15kg-cm)

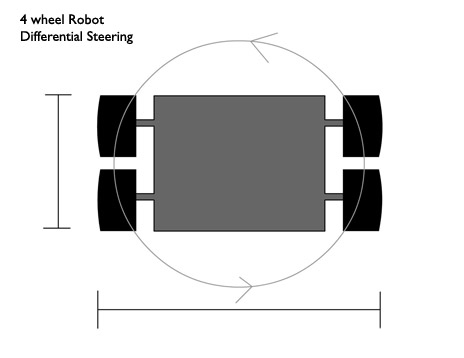

CHASSIS MODELLING -4 WHEEL DRIVE ROBOT DESIGN

Here we use differential steering method.

Differential Steering is nothing but creating difference in the speed of the adjacent left or

right wheels to take turns.

For a complete 360 spin at its pivot position the two wheels on each adjacent side (left and right )

must rotate on opposite spin at same speed.

This approach might appear easy, but it is not always efficient with all kinds of 4 wheel chassis.

right wheels to take turns.

For a complete 360 spin at its pivot position the two wheels on each adjacent side (left and right )

must rotate on opposite spin at same speed.

This approach might appear easy, but it is not always efficient with all kinds of 4 wheel chassis.

In this design when the robot takes a zero-radius 360 degree turn (pivot turning), the front wheel

gives almost negligible resistance to the overall circular motion generated by the rear wheels.

Hence the torque applied by motors on each wheels gets properly harnessed,

resulting in better performance without any drag or wheel slip while taking turn.

Notice that turning of the body is not dependent on the wheel slips any more.

Even if we add motors across all the 4 wheels, the result would be still better than other designs.

Hence in this design you would not require omnidirectional wheels, or tank like wheels,

a set of ordinary rubber wheels would do just fine (cost saving).

gives almost negligible resistance to the overall circular motion generated by the rear wheels.

Hence the torque applied by motors on each wheels gets properly harnessed,

resulting in better performance without any drag or wheel slip while taking turn.

Notice that turning of the body is not dependent on the wheel slips any more.

Even if we add motors across all the 4 wheels, the result would be still better than other designs.

Hence in this design you would not require omnidirectional wheels, or tank like wheels,

a set of ordinary rubber wheels would do just fine (cost saving).

Some of the advantages that you get is out of this design are :

- No loss of torque, fast turning, no wheel slips while turning, better traction on wheels,

cost saving by use of regular wheels.

- No loss of torque, fast turning, no wheel slips while turning, better traction on wheels,

cost saving by use of regular wheels.

CIRCUIT DIAGRAMS

1.ESP8266 flashing circuit

Components: AMS1117 voltage regulator,USB to ftdi module

mini usb b cable,9v battery

Software:ESP Flash downloader

- TX ESP8266-RX USB TO FTDI

- RX ESP8266-TX USB TO FTDI

- CH_PD ESP8266-VCC

- GPIO 0-GND

2.ESP8266 with arduino mega

- To avoid ESP8266 resets a decoupling capacitor 0.1uF is placed between VCC and GND of esp8266

3.Servo motor with arduino

The movement of the arm is made possible using 3 seros(35kg-cm,2x15kg-cm)

4.Arduino with ultrasonic sensor

5.DC geared motor-Arduino-Motor drive

6.Arduino with metal proximity sensor

PROGRAM CODE